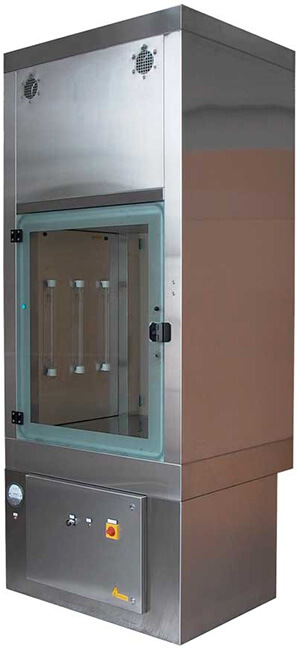

TechGen Ventilated Pass Boxes equipment work to transfer material between areas with different cleanliness grade. The materials may cross the Pass Box in both directions by different handling operations through two interlocked doors.

The basic unit can be variously featured with sterilization or decontamination cycle ( like germicidal lamps or hydrogen peroxide decontamination or sterilization mode ) to deliver the appropriate cleaning procedure according to the application to be performed.

Principle

Pass boxes devices may operate both in negative and in positive pressure without compromising the safety and cleanliness performances. The pressure pattern set up and operational mode, mostly depends on the lay-out of the clean room or to meet specific standard requirements. They operate as standard in negative pressure in comparison to the pressures of the surrounding environments generating that so called “well of pressure“.

Positive step of pressure: the inside pressure is higher in comparison to not clean side area and lower than clean side area.

Overpressure: the inside pressure is higher in comparison to not clean side and clean side areas.

Well of pressure: the inside pressure is lower in comparison to not clean side area and clean side area.

Specifications

Body structure fully made in stainless steel AISI 304L press-bent metal sheets with radius of 3 mm for easy cleaning and roughness lower than 0,8 Ra.

Stainless steel internal side surfaces made in AISI 304L with rounded corners: one piece perforated work surface with 5 mm holes for perfect laminar flow shape made in AISI 304L stainless steel. Collecting sink below work surface in AISI 304L stainless steel.

Equalizer and protective H14 HEPA/ULPA filter diffusor grid made in anodized aluminum.

Glass screens: doors are made from 10 mm thickness safety glass with AISI 304L stainless steel hinges and electro-magnetic handles to open the screen.

Filtration: Class H14 HEPA/ULPA filter. Typical efficiency of 99.995 % MPPS down to particles size of 0,12 μ according to CEN EN 1822.

Recessed control box with opening towards not cleaning area.

Functional backlit switches positioned on the frontal face of the hatch of the box with operating switches and lights indications, in both clean and dirty side area.

FR

FR  EN

EN